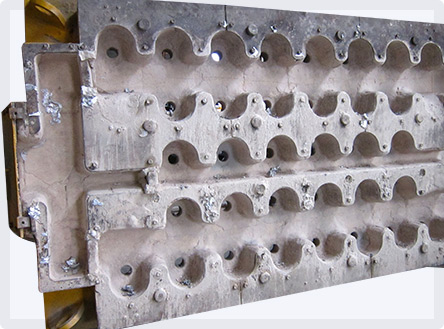

Die Cast: Speed Meets Solid

Unlock the potential of high-volume manufacturing with Vodash Engineering's advanced die casting capabilities. We specialize in creating intricate, durable metal parts with superior dimensional accuracy and surface finish. From initial design to final production, our engineering expertise ensures cost-effective and reliable solutions, empowering your products to excel in today's competitive market. Choose Vodash Engineering as your trusted die casting partner.

Advantages

-

High Production Speed: Die casting allows for very fast cycle times, enabling the production of a large number of parts quickly.

-

Excellent Dimensional Accuracy and Repeatability: The process consistently produces parts with tight tolerances and high accuracy.

-

Smooth Surface Finish: Die-cast parts typically have a good surface finish, reducing the need for secondary finishing operations.

-

Cost-Effective for Large Volumes: While tooling costs can be high, the cost per part is very low for large production runs.

-

Ability to Produce Complex Shapes and Intricate Details: Die casting can create parts with complex geometries and fine features.