About VODASH Engineering

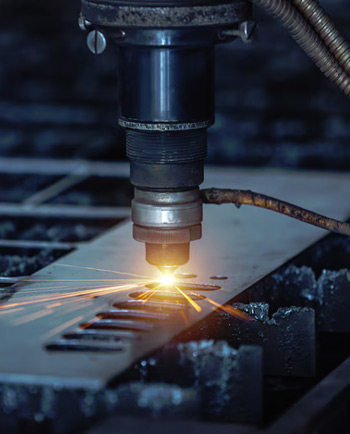

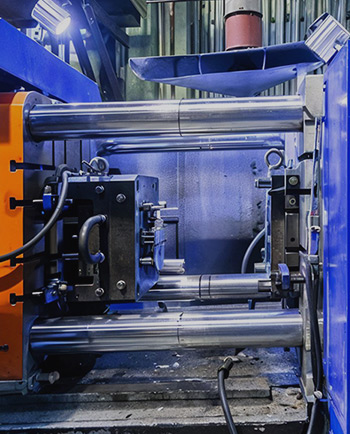

VODASH Engineering specializes in providing top-notch investment casting solutions. With years of experience and a commitment to quality, we serve a wide range of industries including aerospace, automotive, medical and oil & gas industries.

Our state-of-the-art facilities and skilled workforce ensure that we meet the highest-standards of precision and reliability.